FIRE PUMPS & SYSTEMS

Since the 1880s, A C Fire Pump has been a leader in fire pump manufacturing. Today, we design and custom-build modern fire pump systems capable of handling almost any fire protection job in commercial buildings, factories, institutions, and tall buildings.

A C Fire Pump is a member of the National Fire Sprinkler Association (NFSA) and the American Fire Sprinkler Association (AFSA). NFSA supports education, engineering, and public fire protection plans. AFSA promotes proper automatic sprinkler system installation, advanced technology, and smart fire protection practices.

A Shared History of Excellence

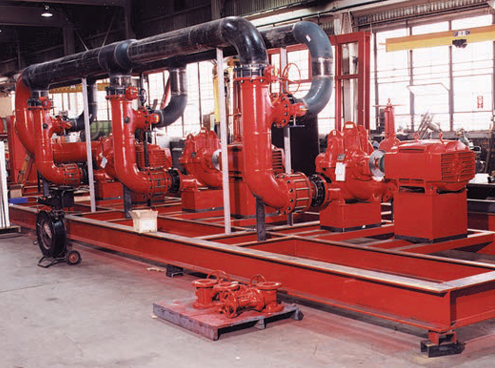

One of the first motorized fire trucks in the late 1800s used an A C fire pump. For over a century, A C Fire Pump Systems has remained a top provider, designing and custom-building fire protection pump systems and pump houses for all requirements. Notably, we supplied fire pump packages for NASA’s Kennedy Space Center launch pads 39A/39B, including four 12×8×22 9100 series horizontal split case pumps powered by 1,065 hp diesel engines, each moving 3,500 gallons per minute at 250 psi.

One of the first motorized fire trucks in the late 1800s used an A C fire pump. For over a century, A C Fire Pump Systems has remained a top provider, designing and custom-building fire protection pump systems and pump houses for all requirements. Notably, we supplied fire pump packages for NASA’s Kennedy Space Center launch pads 39A/39B, including four 12×8×22 9100 series horizontal split case pumps powered by 1,065 hp diesel engines, each moving 3,500 gallons per minute at 250 psi.

NFSA activities include engineering, training, education, and public fire protection programs designed to create widespread acceptance of competently installed automatic fire sprinkler systems in both new and existing construction, from homes to high-rise buildings.

AFSA supports the merit shop automatic fire sprinkler contractor through educational and training programs that maintain the quality and effectiveness of automatic fire sprinklers. AFSA encourages an expanded role for automatic fire sprinklers in protecting lives and property, disseminates information on labor, technology, and business, and provides programs to enhance business practices for the merit shop contractor.

Why Choose A C Fire Pumps

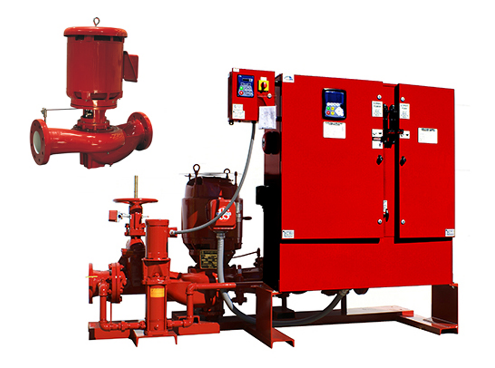

Our fire pump packages come ready to use with code-compliant features:

Benefits of Code-Compliant Fire Pump Systems

Key Design & Installation Considerations

Common Product Features

Who We Serve

Advantages of A C Fire Pump Systems

Frequently Asked Questions

A fire pump system supplies the right water pressure and flow to sprinklers, hydrants, and hose reels during a fire. Without it, sprinklers may fail to control a fire, making fire pumps essential for safety in most commercial, industrial, and tall buildings.

All systems comply with NFPA 20, and components like pumps, controllers, and engines are UL Listed and FM Approved, ensuring full compliance with international fire safety and insurance standards.

Selection depends on building type, water requirements, sprinkler design, and local codes. Our engineers perform detailed flow calculations to determine the correct pump type (horizontal split case, vertical turbine, end suction, or in-line) and ensure reliable performance.

Factory-made packages simplify installation, reduce site errors, and ensure all components—valves, controllers, wiring—are pre-tested and compliant with NFPA standards, enabling faster setup, reliability, and safety.

A-C Fire Pump Systems and Professional Fire Protection

A Shared Tradition of Excellence One of the first fire trucks built in the late 1800’s was

equipped with an A-C Fire Pump. For over 100 years, A-C Fire Pump Systems has been on the

forefront in developing, designing and custom-building a wide range of fire pump systems

including prefabricated packages and house units that meet every fire protection need. A-C Fire

Pump is not only rich in history, but on the cutting edge of new technology as demonstrated with

our contribution to the fire protection systems for launch pads 39A and 39B for NASA at the

Kennedy Space Center. A-C Fire Pump Systems furnished a package of four 12x8x22 9100 series

horizontal splitcase pumps driven by huge 1065 horsepower diesel engines including

state-of-the-art control systems. Each pump is rated at 3,500 gallons per minute at 250 psi

pressure. We will continue to be the leader in the fire protection industry providing both

excellent service and superior products for years to come. You can always count on A-C Fire Pump

Systems to solve your pumping problems

In-Line Pumps

Capacity to 1500 GPM

(5,678 L/min)

Pressures to 165 PSI (116 m) Working Pressures to

150 PSI

End Suction Pumps

Capacity to 500 GPM

(1,892 L/min)

Pressures to 150 PSI (106 m) Working Pressures to

250 PSI

Vertical Turbine Pumps

Capacity to 5000 GPM

(18,925 L/min)

Pressures to 350 PSI (247 m) Working Pressures

up to 200 PSI with 125 lb. A.S.A. flanges

up to 550 PSI with 250 lb. A.S.A. flanges

up to 200 PSI with 125 lb. A.S.A. flanges

up to 550 PSI with 250 lb. A.S.A. flanges

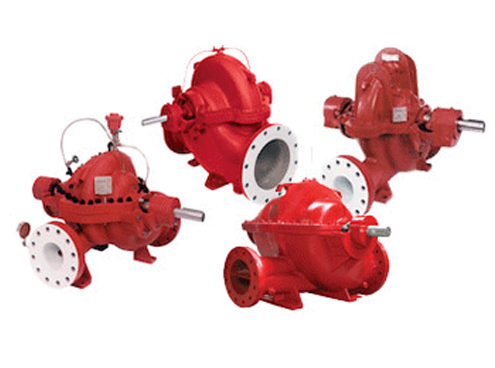

Split Case Pumps – Single Stage

8100 Series

Capacity to 3000 GPM

(11,355 L/min)

Pressures to 255 PSI (179 m) Working Pressures

8150 Series

Capacity to 5000 GPM

(18,925 L/min)

Pressures to 233 PSI (157 m) Working Pressures

9100 Series

Capacity to 5000 GPM

(18,925 L/min)

Pressures to 208 PSI (146 m) Working Pressures

Split Case Pumps – Two Stage

8200 Series

Capacity to 1000 GPM

(3,785 L/min)

Pressures to 640 PSI (450 m) Working Pressures

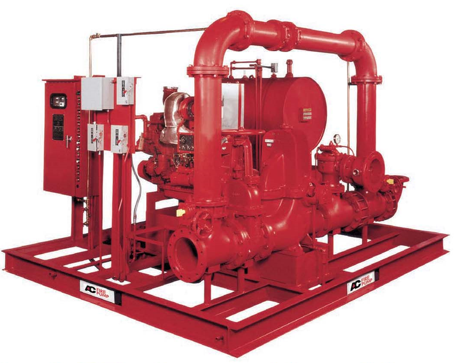

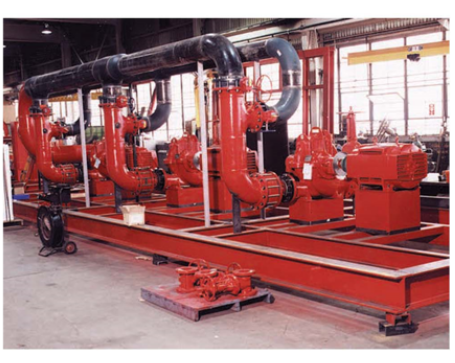

Skid Packages

With A-C Fire Pump Systems you can rest assured of start-up and future product support being

available locally, worldwide.

Select A-C Fire Pumps with confidence

House Packages

Customised Water Management Solutions

Don’t cut corners, cut your costs.

Get complete water management solutions customised to your budget and requirements.